From bauxite to aluminium

With about 8 % by weight, aluminium is the third most abundant element in the Earth’s crust after oxygen (47 %) and silicon (26 %). Aluminium does not occur freely in nature, only in aluminium compounds such as clay and bauxite.

In terms of industrial archaeology, aluminium is a quite young metal. The discovery of electrolysis by Hall and Héroult in 1886 made it possible to produce and process aluminium on a large scale.

Today aluminium extraction is almost exclusively carried out in two stages: aluminium oxide is first extracted from bauxite in the so-called Bayer process and the metal is then extracted from the oxide in aluminium smelters using fused-salt electrolysis. As a rule of thumb you get 1 kg of aluminium out of 4 kg of bauxite in this process.

The bauxite-exhaustion fields are recultivated by the aluminium industry. 70 % of the fields are afforested, 20 % are used for forest or agricultural needs and 10 % are developed for residential, recreation and industrial areas.

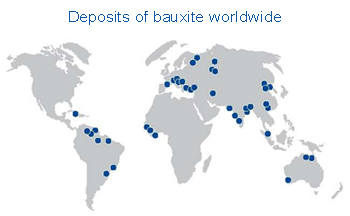

Known bauxite reserves, which are spread across all continents but can mainly be found in tropical areas, are estimated to be about 25 billion tonnes. So resources for primary aluminium production will be available for several hundred years to come.

Since the electrolysis process for the production of aluminium is quite energy intensive (between 13 and 15 kilowatt-hours per kilogramme), about 57 % of electricity used worldwide is from hydroelectric power in order to produce the metal as economically and environmentally friendly as possible.

For more detailed information on aluminium you can go the the following websites:

www.aluinfo.de

www.aluminium.org